Description

The Thamrin Nine Tower 1 will be the tallest skyscraper in Indonesia, standing at 333.5 m with 70 storeys. Located in the historical and social hub of Jakarta, this mixed development project has two residential towers joined by a retail podium reaching up to the fourth floor, offering a total of 470,000 m2 of space.

Solution ULMA

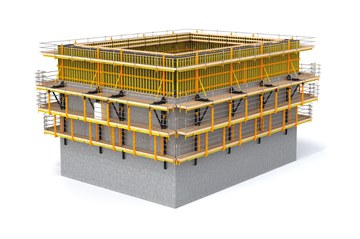

Given the height of the structure, the primary core was executed using the Self-Climbing ATR System combined with ENKOFORM VMK Timber Beam Formwork. The flexibility of this combination made it possible to complete the entire core – including walls and intersection of walls – in a single pour.

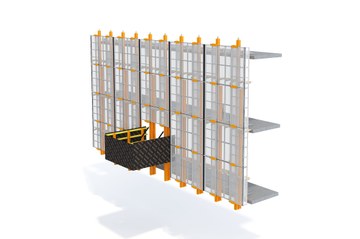

The ATR System is designed with brackets and roll-back trolleys as well as MK structures that allow the panels to be hung even in extremely restricted spaces, thus facilitating not only formwork movement and advance, but the installation of rebar reinforcement as well.

While construction was underway, changes were made in the design of the steel infrastructure between storeys 34 and 36, which impeded the advance of the self-climbing structure. With only a few changes to the anchorage points and the pouring heights, these obstacles were easily overcome.

HWS Screens protected against adverse climatology and falling objects from three storeys simultaneously. The building features three sections with distinct geometries and perimeters. From the 11th to the 55th storeys, the floor height is 4.45 m, while from the 55th to the 59th, the height changes at every storey, and from the 59th to the 68th, the height is 3.80 m. The versatility of the construction system made it possible to adapt to these changes in geometry and perimeter with ease. In addition to hydraulic elevation, the system also offers simultaneous protection for three storeys.

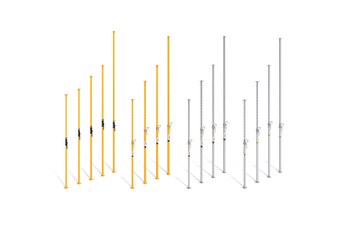

With the perimeter fully secured, the slabs were poured using VR Tables and SP Props. This is the ideal solution for thinner slabs with hanging beams, typical of construction in Southeast Asia. ULMA’s comprehensive solution also included the ENKOFORM VMK System for other structures, such as columns and the remaining walls.