Description

To construct power plants of these dimensions an enormous quantity of material is required. For this project in particular, more than 2,000 t of material were supplied. In such situations it is critical to have distribution centres located near the worksite. This is what allowed us to achieve our completion times and reduce costs for the customer.

This new hydroelectric power station, Venda Nova III, with a total production capacity of 746 MW, significantly increased the energy production of the country as a whole.

ULMA Solution

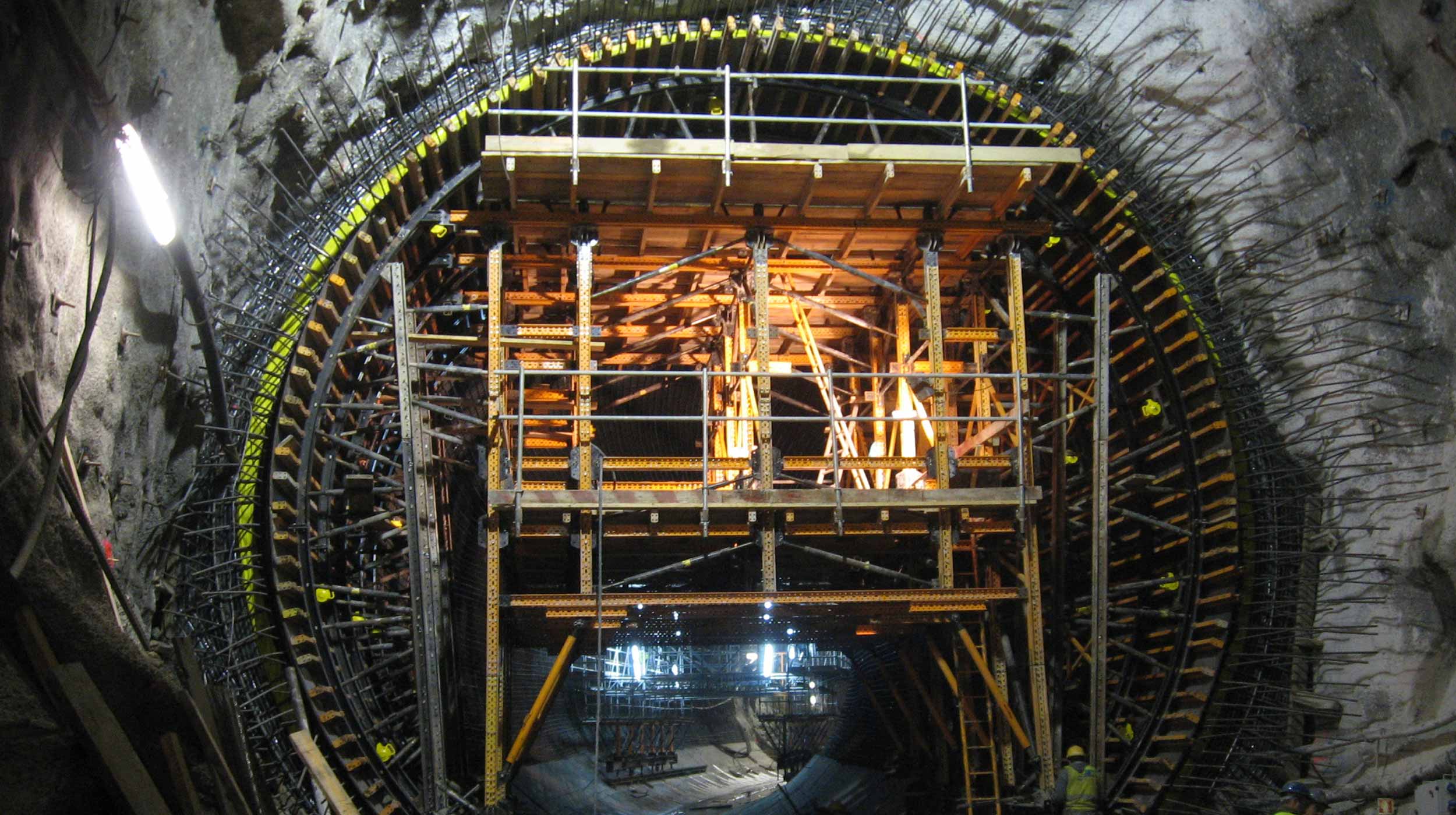

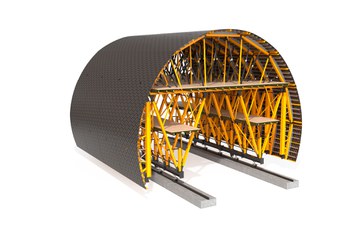

For this project, with more than 9 km of subterranean galleries, standardised systems were employed to adapt to the different geometries and the completion times agreed upon with the client. Tunnels with diameters varying between 8 m, 16 m, and 20 m were built using simple assemblies.

To place the rebar and clad the tunnel walls, BRIO scaffolding – also serving as gantry falsework – was installed on an MK carriage, which allowed it to move along the entire length of the tunnel. It is worth noting that in BRIO scaffolding alone more than 300 tonnes of material were provisioned.

For tunnels with diameters greater than 20 m, the ENKOFORM system was used as a mixed shoring and formwork structure, combining versatility with the load-bearing capacity of ULMA shoring systems.

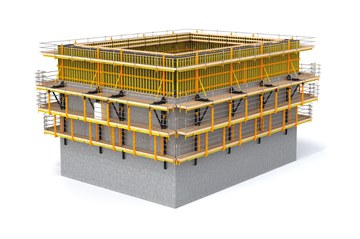

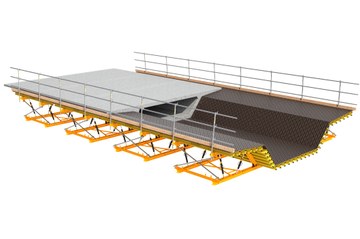

The walls of the plant’s mechanical systems, the tunnel sidewalls, and the lateral beam faces were all built using more than 1,400 m2 of ORMA modular formwork. The ATR self-climbing system was used to build the single-faced surge tanks, measuring 358 m in height, in 3.5 m pours.