Description

As part of the first phase in the expansion of the A-4 Motorway, this project includes both the construction of a new tube 367 m in length and the renovation of extant tubes. The new tube, located just north of the original tunnel, will have four separate lanes for traffic travelling from Amarante to Oporto; the original tubes will provide passage for traffic in the opposite direction. The project is designed to drastically improve travel conditions for traffic going in and out of the city of Porto.

One of the complexities posed by the project was its location in an urban centre with significant geotechnical risk, characterised by thin soil cover and areas of extremely weathered granite.

ULMA solution

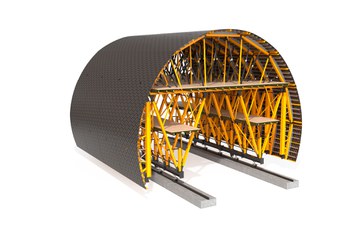

ULMA’s technical team developed three separate structures in partnership with the client, in order to make work as efficient as possible. First, a BRIO-MK scaffolding carriage was used to waterproof the entire tunnel. A similar carriage was then used to install the rebar. In both cases, ULMA’s most versatile systems were combined to create carriages adjusted and optimised to meet the demands of the project without any need for oversizing. Afterward, the MK formwork carriage was used to pour the tunnel structure itself. With a single carriage it is possible to create all of the dimensional variety needed for a tunnel, a facet that proved ideal for this tube design with four distinct sections, each varied at the bottom. As an additional benefit, the carriage allowed for the passage of vehicles during construction, which is a necessity in such projects.

The MK Carriage is a high-performance, flexible solution. It offers high load-bearing capacity without compromising the ability to adapt to different sections.

The carriage features hydraulic equipment to facilitate formwork installation and stripping, as well as lowering, levelling, and advancing the entire assembly.

Using a single MK formwork carriage 12.1 m long, 10 m tall, and 19.2 m wide, the tunnel was entirely completed in three months, including assembly and disassembly.

The pace of work exceeded client expectations. Work cycles were approximately a day and a half, with 10 to 11 hours of pouring and 3 hours for advance and adjustments. Thus four cycles were completed on a weekly basis.

| Tunnel length | 366.9 m |

| Longitudinal slope | 0.9876% |

| Floor plan radius | 1078.67 m |

| Formwork length | 12.125 m |

| Thickness | 500-1150 mm |

| Width | 19.2 m |

| Height | 10 m |

| m² of formwork | 388 m² |

| Section/pour volume | 230-250 m³ |