Description

ULMA Construciton has contributed to the infrastructure improvement in the Basque Country through the construction of the Eskoriatza North-Arrasate North stretch, which is part of the Eibar-Vitoria Highway.

Several projects have been completed within this stretch, such as the Izurieta-Apotzaga tunnel covering 260 meters,which opens out onto the Basagoiti viaduct, of 427 meters, designed to save the existing river bed. Additionally, there are two overpasses that allow overcoming the complex orography.

The Basagoiti viaduct is 427 m long and consists of three V-shaped piers, with 35 m spaced bearings, anchored to a plinth. The cross section is rectangular, 2.25 m high and 5.50 m wide. The axes of the bearings form a quasi-right angle.

ULMA solution

For the execution of the piers, the same products and the same process were used in all three cases: formwork with walers and beams over H-33 Trusses, sufficiently long for the concrete pouring of both stages, 35 m in length. Additionally, the HM-500 beam Formwork gangs were made with plywood, beams and walers. The entire assembly was supported on H-33 Trusses, positioned 0.5 m from each other. The gangs were joined by means of tie rods. The load transmission from the piers to the ground was done through two sets of T-500 towers. Loads were also distributed to the pier plinth through profiles with anchor bars and formwork stripping wedges.

In order to prevent deformation and cracks in the concrete when stripping the system, the pier was left supported on the end towers and anchored at half height.

Self-compacting concrete was used in the pouring process of the piers, which means that vibrators were not required. This way, a better concrete quality and finish was achieved and the appearance of imperfections was prevented.

The system applied in the Izurieta-Apotzaga cut and cover tunnel consisted of a formwork carrier trolleyable to cast the tunnel’s complete section. To move the formwork from a stretch to the following one, the trolley, supported on its rolling system, was pulled along a rail beam.

ULMA's Engineering Division designed a light structure able to move a large BIRAMAX Vertical Formwork area without the need of external auxiliary means. An impressive performance was achieved while keeping high safety standards and low execution costs. This was also possible thanks to the use of a hydraulic drive for both longitudinal movement along the tunnel axis and for the formwork stripping.

The total trolley length was 12.25 m, including 17 cm overlap with the previous phase and 1.30 m at the front to fix the stopend and the working platform.

The BIRAMAX panels were fastened to longitudinal walers (joined with connectors and 20x70 pins), whose function was to provide support points for the upper formwork panels. These walers also allowed passing the anchors through the panels to connect them with the truss support. These pieces withstand the concrete pressure and guarantee the whole stability during the work stage and when the formwork is changed.

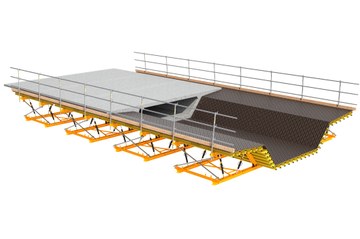

Within this same highway stretch, ULMA completed the assembly of the falsework and the formwork of the Overpasses 13 and 16. The solution for executing such an overpass was given with ENKOFORM HMK Formwork and with falsework supported on foundations. Additionally, in the areas near the abutments, a solution for overcoming the slope was applied by means of a series of heavy duty laminated profiles.