Mainly used in the civil engineering industry, the T-500 shoring tower is designed to bear heavy loads. It is mainly intended for the construction of bridges or viaducts of great height by means of the gantry shoring system construction method.

It is also ideal for the construction of bridges, where the filled falsework method cannot be used due to ground conditions.

In short, this modular shoring provides optimal performance for heavy loads at significant heights with many spans between supports.

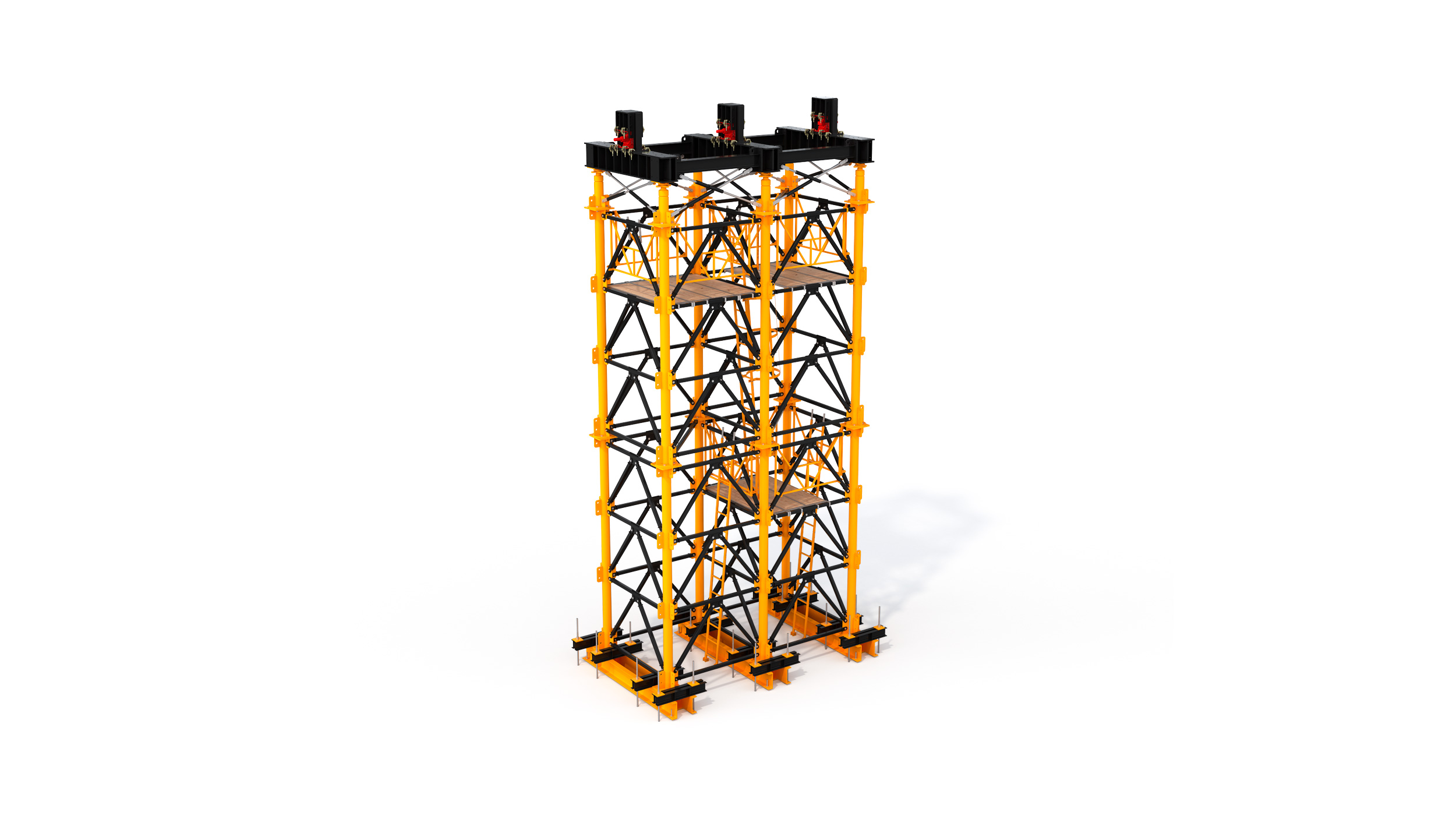

- The system comprises three main parts:

- Tower base: consists of profiles on which the posts stand

- Central module: modular structures that are bolted one on top of the other until the desired height is reached

- Tower head: consists of the head screw jacks with the head beams on top of them, which act as load distributing profiles to support any other structure on them

- Tower configuration modulation plan view: 2 x 2 m and 2 x 3 m

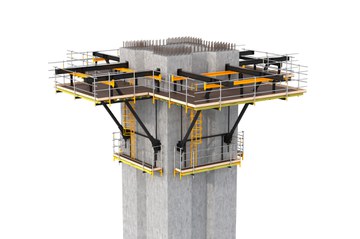

MT BRACKET

This is a pier load bearing bracket for the construction of bridges, avoiding direct shoring towards the ground. It is designed for use in very high piers or entrances and complex shoring areas on the ground. The MT bracket is mainly used with gantry falsework construction method.

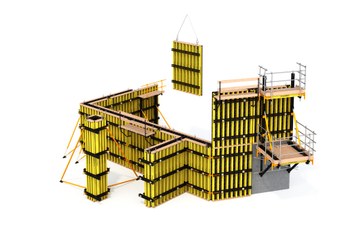

- For its high load capacity it only requires a minimum number of supports

- Quick and safe on-site erection

- Can be completely dismantled. Easy storage and transport due to small volume of parts

- Stripping with shoes and head posts

- Modular system can be adapted to different heights

- Erection as independent or chain-linked towers

- Use with wind bracing system optimises the solution as it minimises material quantities

- Safe system: platforms for the reception of modules, protective handrails and accesses between them

MT BRACKET

- Combined with the shoring tower, this is a cost-effective solution reducing the shoring material to be delivered to the site

- Does not require construction of windows in piers

- Uses the same stripping elements formwork items that are used at the top of the heavy duty shoring towers