Description

ULMA welcomes more and more difficult challenges every day, such as that presented by the construction of the skyscraper Q22 in the Polish capital, a tower 155 m tall built in only 20 months.

It is a 47-storey office building, with 5 storeys below ground level. Thanks to its sustainable and efficient design, the project received the “BREEAM Interim Excellent” award, scoring the highest of any building of its category in Poland.

ULMA Solution

ULMA found a solution for the four building cores, each of which have different cross-sections, using the same self-climbing systems: ATR and RKS. The geometry of the building is irregular, with cores 1-3 varying from floor +40 and core 4 ending at floor +15.

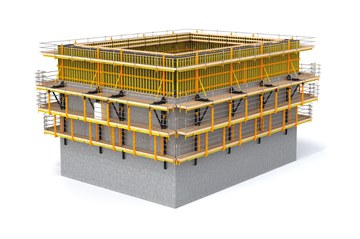

Standard ATR-P self-climbing platforms were used for the first two cores. The solution included three working platforms and a load-bearing structure supporting the ORMA modular formwork.

The third core, larger than the rest, required a fourth working platform in the lower area, so as to make use of the formwork for the transverse walls anticipated in a second phase. The climbing system employed ATR-P telescopic heads with ATR-B and ATR-N roll-back carriages. With this self-climbing system it was possible to raise the formwork assembly 50 cm above the slab, as well as roll it back from the wall to any distance required.

For the fourth core, KSP shaft platforms were used in the interior as a traditional climbing system and self-climbing formwork on the exterior. The gangs were guided on the wall throughout the lifting phase, making the entire assembly agile, versatile, and safe.

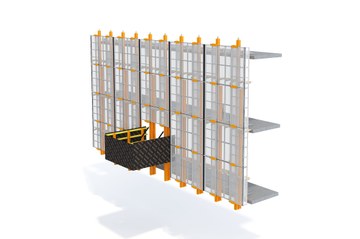

In projects of this type worker protection from both falls and inclement weather is paramount, which is why the building perimeter was covered using 42 protective screens. The HWS system once again proved its ability to adapt easily to the exigencies presented by both the design and the surrounding environment, providing a material storage platform and adjusting to the irregular façade and slab geometries presented.

BMK brackets and ORMA modular formwork fitted with three levels of working platforms and perimeter handrails were used to construct the inclined wall that crosses part of the building, from floors 2-8. At height, the beams were built using ORMA formwork on BRIO falsework.

ULMA developed a special load-bearing structure for the water tank located on the 15th floor of the fourth core. Its purpose was to shore the reinforced concrete structure supporting the tank. The structure was built using eight MK trusses 2.5 m wide and 8.2 m long. It is embedded in the walls with MK nodes.