Description

This project has made it possible to provide potable water to more than 2 million people. Many of them receive drinking water for the first time and others extend their supply schedule to 24 hours.

The work consists of the construction of a hydraulic water collection structure, located on the right shore of the Rimac river, and the edification of a water treatment plant in Huachipa. Additionally, a 27 km long channel was made, which includes 2 tunnels (5 km each) and 5 tanks with capacities of 2,000 and 9,000 m3.

ULMA Solution

NEVI Modular Formwork was used to build the walls, both single and double-sided. In fact, 8.20 m high walls were built with this system in the hydraulic water collection structure.

Thanks to their structure and anchoring system, made up of tie rods and plate nuts, these panels supported the high concrete pressures that are characteristic in this type of construction.

The lightness and the quality of the NEVI items enabled easily and efficiently handling the formwork with and without a crane. As a result, high execution rates were obtained in this project.

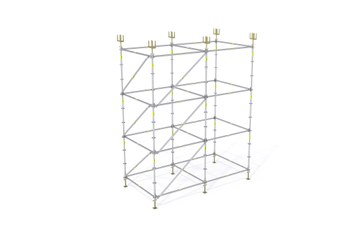

Using BRIO scaffolding, working platforms were created that also served as transit areas in the case of high and difficult to reach areas. BRIO falsework was used as a shoring system for 20 to 30 cm thick slabs. This system, versatile and safe, can be applied from simple solutions to the most complex and diverse ones. The reduced number of parts that make up the system enable a simple and fast erection.

For the construction of the 77 billion m3 tank, the innovative MK system was the system chosen. Its special features make it the most flexible system, able to adapt to any geometry. Among others, it is specially suitable to make the formwork for circular walls.