Description

Covering approximately 230,000 square metres, the Real Plaza Puruchuco project has required specialised and innovative construction techniques, relying on ULMA’s technical and logistical support throughout the entire process.

The Real Plaza Shopping Centre is considered to be one of the country’s most ambitious retail projects to date, with an estimated 2 million visitors in the first year alone. The Centre is expected to draw people from around the district of Ate, as well as the districts of La Molina and Santa Clara, thereby providing economic and social development opportunities across an extensive metropolitan area.

ULMA solution

More than 2,000 tonnes of formwork and scaffolding have been used, most notably NEVI and the COMAIN handset panel formwork system for walls and columns, combined with the easily adaptable ENKOFLEX timber beam slab formwork system, providing a superb finish for exposed slabs.

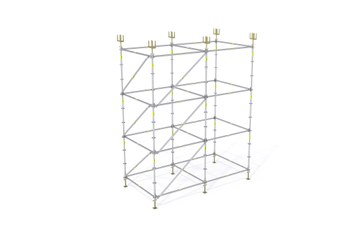

ULMA provisioned BRIO shoring and ALUPROP aluminium props along with OC Shoring as falsework for the horizontal structures. Multidirectional BRIO scaffolding was used to provide worker access throughout the site, providing safe working areas for rebar installation, concrete pouring, formwork stripping, material storage, and other needs.

ULMA’s Technical Instructors provided training and oversaw all personnel in the proper use of both scaffolding and formwork, ensuring the safety and efficiency a necessary to meet the demanding project deadlines.

Without a doubt, this is a flagship project for ULMA, which during its eighteen years working in Peru has participated in the majority of the country’s commercial centre construction and expansion projects, demonstrating its highly developed response capacity in both logistical and technical solutions. ULMA’s Engineering Department dedicated more than 4,000 hours to complete this project, demonstrating their technical capacity to offer cost-efficient and safe solutions for scaffolding and formwork.