Description

Located at the southern end of Weehawken's Lincoln Harbor, the 800 Harbor Boulevard residential building has been designed by Marchetto Higgins Stieve Architects, recently named by the American Institute of Architects of New Jersey as "Signature of the Year 2019".

This building project of three towers of 15-stories is being built in one phase and will host 573 apartments and 719 parking spaces, covering a space of 275108 m² that includes 15850 m² of amenity space. The luxury residential complex adds to many other construction projects undertaken in the Lincoln Harbor area of Weehawken, which is in the expanding period, growing in popularity because of its central location and its wide range of entertainment services and public transportation that makes it easy to connect New York and New Jersey cities.

ULMA solution

ULMA's participation in this building project consists of the offer of comprehensive formwork and shoring solutions, together with continuous commercial, technical and logistics assistance, maintaining a close relationship with the customer Roy Rock LLC and offering a reliable service during the development and execution of the project.

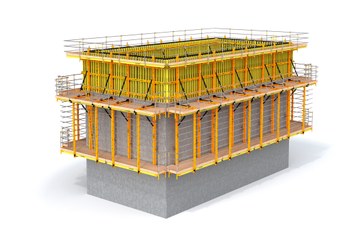

ULMA provided the Handset Panel Formwork MEGALITE system for the construction of walls and columns, which is an ideal vertical formwork system that help to meet the deadlines of any concrete construction project because of its versatility and productivity. This modular formwork system was also used in the core of the building, erected with MEGALITE gangs. The lightweight panels allow easy handling and a quick connection by using the MEGALITE Clamp. In total, around 13106 m² of LIGHT formwork MEGALITE have been delivered on the jobsite.

For the execution of the exterior wall of the building, the proposed option has been the Rail Climbing Formwork RKS that allows hydraulic climbing without detaching the structure from the wall. A flexible and safe system for the construction of high-rise buildings, which allows safe lifting operations in adverse weather conditions.

The contractor, Roy Rock LLC used ENKOFLEX Timber Beam Slab Formwork to build all the concrete slabs. This system is the most appropriate due to its versatility and ease of assembly, allowing adaptation to height requirements that vary between 3 and 4.27 m, thus offering great productivity and safety on site. As for the shoring of the slabs executed by the ENKOFLEX system, ULMA has offered ALUPROP aluminum shoring post designed to support high loads. In addition to the ALUPROP certified props, ULMA considered as a best solution the use of the MEGAFRAME propping system to meet the requirement posed by the design of the building with a slab height of 7 m. on the third floor. Thus, about 2750 m² of MEGAFRAME were used in the jobsite.

The close relationship and the continuous communication between the two companies, have a positive impact on the achievement of high productivity and safety during the execution of the work. According to the client this understanding has been possible thanks to the involvement and commitment shown by the ULMA team, the quality of the products offered, in addition to their capacity and speed of response, resolving on site the demands posed by this demanding building project.