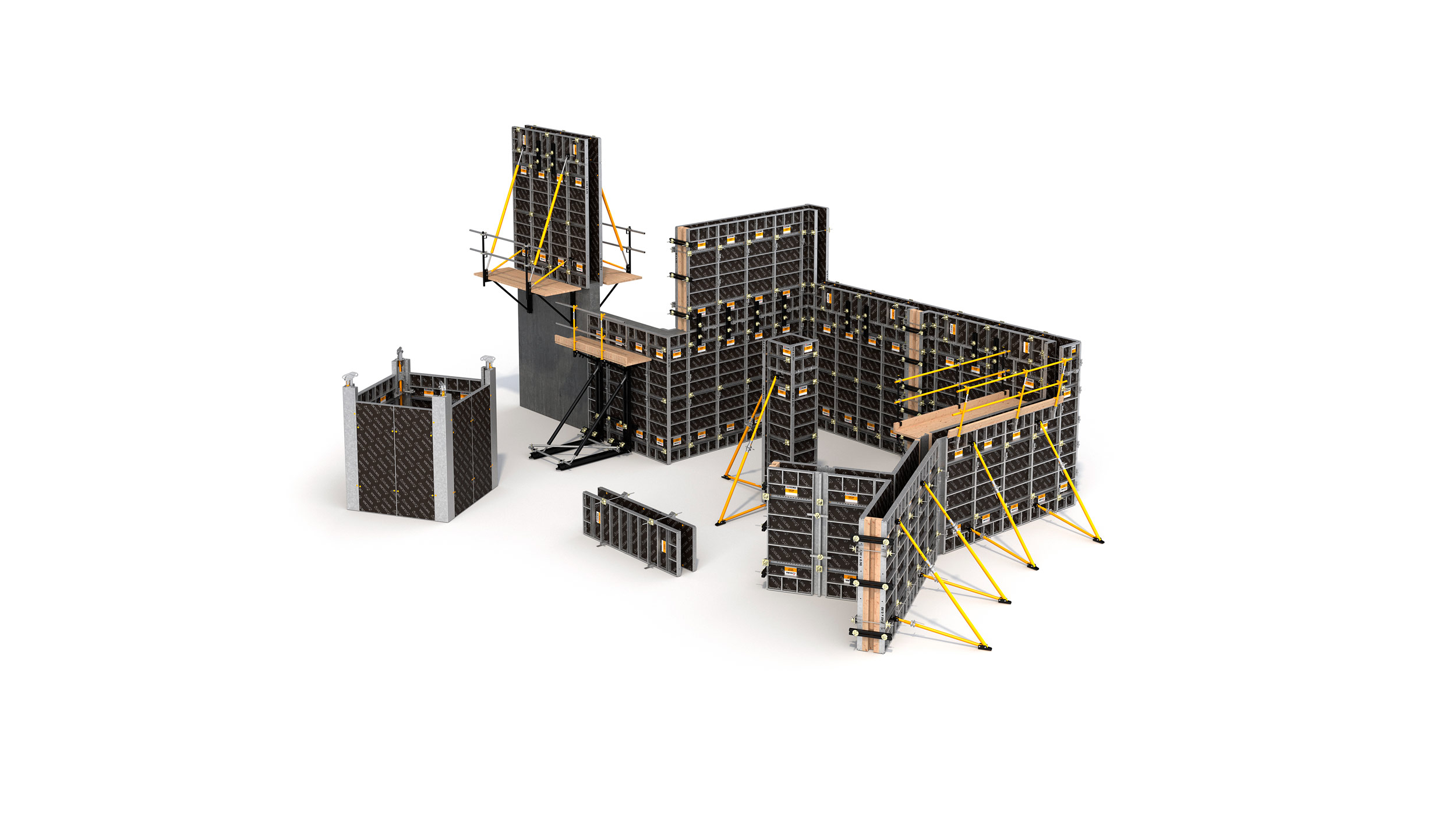

The LGW-MP multipurpose panel formwork is a versatile system for the solution of any vertical geometry in building construction.

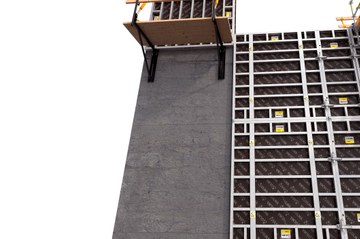

Minimises assembly operations thanks to an optimised number of tying points and joints between panels.

Remarkably strong and durable panel design with galvanised or painted frames and phenolic board.

- LGW-MP allows on-site flexibility by adapting to any planning changes. Panels meant to form columns could go to make walls or vice versa anytime.

- Easy to use perforated frame rib system to form the columns.

- Minimizes the possibility of assembly mistakes.

- Quicker and more basic training process.

- High load capacity panels:

- Maximum constant pressure: 60 kN/m2.

- Maximum hydrostatic pressure for the 3 m panel range: 75 kN/m2.

- Maximum deflections: line 6 according to DIN 18202.

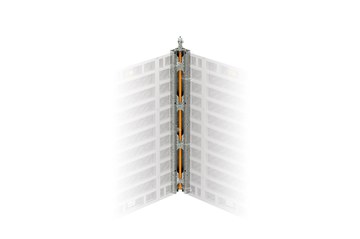

- Columns:

- Widths from 15 to 75 cm.

- Maximum constant pressure: 60 kN/m2.

- Rectangular columns can be formed with one or more than one panel on the long side.

- Wide panel rage:

- Height: 3 m, 2.4 m, 1.2 m, 0.6 m.

- Width: 0.9 m, 0.75 m, 0.6 m, 0.45 m, 0.3 m.

- The shuttering face comprises a 15 mm phenolic birch plywood, providing an excellent concrete finish.

- Payed-off investment:

- Up to 10% lighter than similar systems.

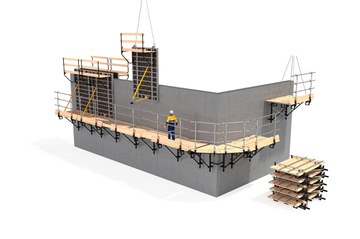

- It can be manually assembled reducing crane use on-site.

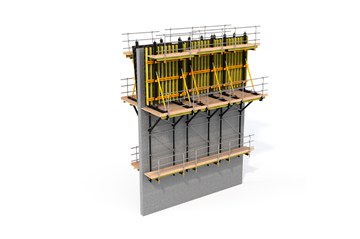

- Gang forming available for fast forming.

- Designed to last:

- High durability, hot-dip galvanised or painted panels.

- Reinforced steel frame on the corners protected against the damage of impact.

- Easy to replace the board when required.

- No crane required:

- Up to 9% lighter than other similar systems.

- The LGW-MP panels are assembled manually, which reduces the use of the crane on site, even though the crane operation is also possible.

- Light equipment makes all operations easier and more secure.

- Speed up workflow:

- Optimised number of tying points and joints between panel, minimising tying and infill operations

- Connecting the panels is easy and fast anyway using easy-to-use clamps for the walls and perforated frame rib system for the columns.