A New Healthcare Benchmark in Norway: Drammen Health Park

The ground floor of the complex will extend 440 meters and will house a wide range of shops and services — cafés, florists, bookshops, gyms, restaurants and other businesses — designed to make everyday life easier for patients, staff and local residents.

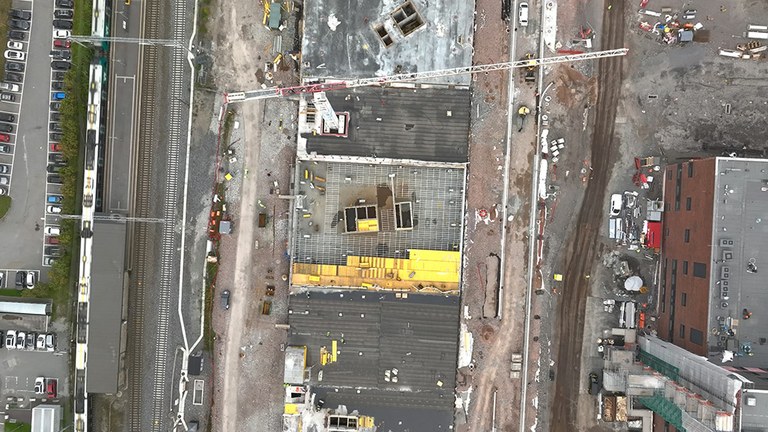

Within the complex, the construction of an 8,800 m² underground car park stands out, designed to serve the entire health district. ULMA has contributed to this project by supplying formwork and shoring systems tailored to the technical requirements and demanding construction schedule.

The car park measures approximately 200 x 40 meters. Along its perimeter, a 3.5-meter-high retaining wall was cast with a single-sided solution — essential due to the underground location of the structure. For this, 20-meter-long SMK single-sided trusses were combined with modular ORMA formwork. This configuration not only facilitated assembly and striking but also effectively and safely addressed a variety of geometries. In addition, its design allowed the material to be reused across different construction phases, optimising resources, labour and installation times.

In the central area of the car park, several stair cores were built. Once again, the ORMA system was employed, complemented by the STRIPPING CORNER MAX, specifically designed to simplify work in lift shafts, staircases and hollow piers. This solution enabled the formwork to be retracted and repositioned quickly and safely, without the need to dismantle the corner from the rest of the panels.

For the construction of the 35 cm thick post-tensioned slab, the works were divided into stages of approximately 1,000 m² each. ULMA supplied the recoverable ONADEK formwork system, combined with EP props and timber beams for edge finishing. The choice of ONADEK effectively met the geometric, flexibility and load requirements typical of this type of slab. Its modular design, along with its ease of assembly and striking, helped maintain high productivity on site.

The access ramps to the car park were built using ALUPROP aluminium towers along with their corresponding supplements, providing robust support for the ONADEK system in sloped areas with complex geometries.

Additionally, auxiliary works and access at height were carried out using the BRIO Multidirectional Scaffolding and BRIO Stairs, which provided safe and comfortable working platforms for the crew throughout all phases of the project. Their simple assembly enabled a high construction pace — a key advantage in environments where meeting deadlines is a top priority.

For more information, watch the video.