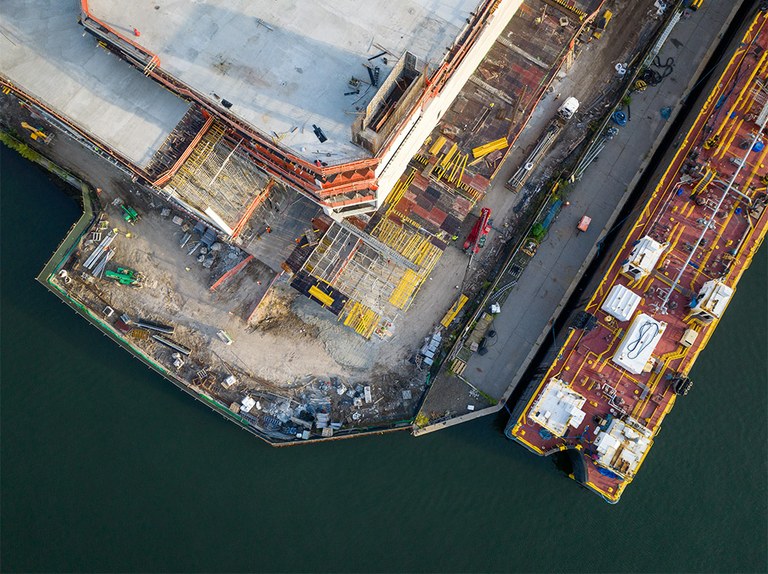

Cutting-Edge Logistics Infrastructure in Brooklyn, New York

ULMA took part in this ambitious project by providing high-performance shoring and formwork solutions for the execution of the building’s structural elements. All equipment was designed and adapted to meet the technical, regulatory and safety requirements of the country’s construction industry. Given the scale and complexity of the project, multiple technical meetings were held to define how each system could be applied in the most efficient way possible.

The work began with the four-level parking structure, where ENKOFLEX beam formwork and the MEGAFRAME shoring system were used to build the slabs and beams with variable thicknesses ranging from 40 to 90 cm. These systems stand out for their flexibility and ability to adapt to different geometries and loads, as well as for their speed od assembly and dismantling, which reduces construction times on site.

Additionally, ALUPROP towers were incorporated to support column heads and slabs at heights of up to 10 metres. Made of aluminium, they combine high load-bearing capacity with a lightweight structure, making them easy to handle, assemble and transport. Their ability to be stacked and braced allows great heights to be reached while maintaining structural safety and stability, and their versatility allows them to meet both initial shoring and reshoring requirements.

For the construction of cores, shear walls and columns, the MEGALITE modular formwork system — supplied in imperial measurements — was used for heights of up to 4.8 metres. This system offers a lightweight, robust and easy-to-handle solution, ideal for projects with tight schedules and high technical demands. It also ensures high-quality concrete finishes and enables a fast and efficient work cycle.

Overall, the use of ULMA’s shoring and formwork solutions made it possible to optimise the construction process, guarantee safety at every stage, and deliver robust, durable structures perfectly tailored to the project’s requirements. The combination of modular, lightweight and high load-bearingsystems facilitated the achievement of project deadlines and quality standards.

Discover more details about this construction project located in Brooklyn in this spectacular video.