Description

Line C, which connects the periphery with the city centre, is going to be the longest public transport route of Italy and the first line of Rome's metro. A unique project in which ULMA has worked at 30 m depth over a length of 25.5 km.

Alessandrino Station:

- Length of 2 parallel tunnels: 115 m

- Variable radius of curvature of 4.29 to 4.9 m

- Formwork carrier length: 12.1 m

- Pouring cycle: 2 days

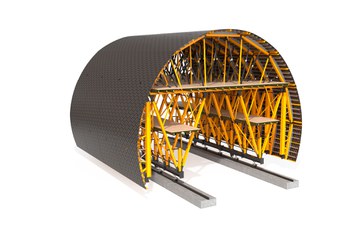

- Assembly: on-site 23 days. The MK form carrier was used in both galleries and divided into modules of 6 m to build the 28 m long tunnel of Centocelle Station.

Mirti Station:

- Length of 2 parallel tunnels: 46 m

- Variable radius of curvature of 4.29 to 4.9 m

- Formwork carrier length: 6.1 m

- Pouring cycle: 3 days

- Assembly: in warehouse. The flexibility of the system eased the lowering of the central portion of the form carrier in every stage to avoid interference with the existing slab.

Malatesta Station:

- Tunnel length: 165 m

- Variable radius of curvature of 4.29 to 4.9 m

- Formwork carrier length: 12.1 m

- Pouring cycle: 3 days

- Assembly: on-site 17 days. The form carrier of the Alessandrino Station was reused by replacing a minimum number of items.

- Divisible: the entire section was 12 m except for the curved areas, where it was reduced to 6 m.

Lodi Station walls:

- Perimeter per floor: 276

- First floor wall height: variable 4.21 - 6.03 m

- General wall height: 6.16 - 6.76 m

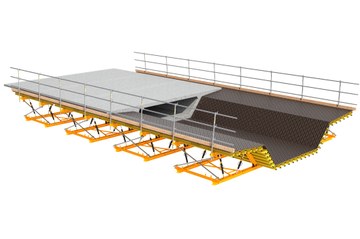

- Pouring cycle: 2 days. With the MK Truss system and beam-based formwork, walls of up to 12 m length were built.

This system, most suitable for long structures, offered solutions to a wide range of tunnel sections regardless of complex shapes or high loads.

ULMA Solution

From the beginning on, ULMA supplied the material and provided its expertise and professional advice in the construction of the underground stations.

The modularity of the MK system made it possible to apply a single solution, and to reuse the form carriers in different galleries with a minimal need for adaptation to the varying geometries.

Safety was built-in in the ULMA systems, since all vertical formwork carriers were equipped with working platforms and ladders.