The GARAGE BEAM SYSTEM is designed specifically for post-tension beams and slab multi-story parking structures, simplifying and reducing concrete construction costs.

The system utilizes standard ULMA components and few elements especially designed for this system, making the assembly and use simple and efficient, increasing productivity with excellent concrete finishes.

- A high level of productivity by forming beams up to 64 ft. long.

- Beams can be formed from 6 to 30 in. wide and up to 40 in. high.

- Beam forms are composed of high-strength GB Panel corners and MEGALITE panels.

- It can support concrete slabs up to 12 in. thick.

- Wide-open bays up to 19 ft. wide are possible without mid-span support for slab deck area reducing re-shoring equipment.

- 100% rentable components saves on lumber and consumables for increased on-site savings.

- Quick assembly

- Easy and intuitive assembly using standard shoring and forming components and simple clamp and/or bolt & nut connections.

- Available pre-assembly for increase on-site productivity and labor savings. The entire system can be ship 90% assembled.

- No need to:

- Build beam from H20‘s and plywood, thus saving construction time.

- Measuring, cutting plywood, consumables, carpentry skills, or special tools.

- Modular & Versatile

- Utilizes 90% standard ULMA components and accessories that can be used for other shoring and forming applications.

- Concrete beams of various sizes and depths are available using MEGALITE panels and accessories. No ties are required.

- Wide range of shoring height applications and high load-bearing capacity with ALUPROP posts.

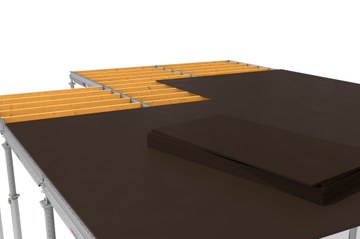

- Construction of slab deck panels with Aluminum joists and plywood.

- Easy to use

- Concrete Beams up to 32 ft. long are moved as a unit with integrated wheels for easy movement around the site.

- GB Panel corners drafted at a 2.4° angle for easy stripping.

- Excellent concrete finish

- Beam forms are composed of high-strength GB Panel corners and MEGALITE panels phenolic plywood face.

- Contractor choice of plywood type and grade for the construction of slab deck panels.