Description

A three-tower luxury residential building with 15-stories each hosting 573 apartments and 719 parking spaces. The towers span 902,855 SF with 52,000 SF of amenity space. It is located at the southern end of Weehawken, New Jersey and is being built in one phase. This complex is just one of the many construction projects in the neighborhood. Weehawken’s Lincoln Harbor area is quickly expanding and growing in popularity because of its central location that offers multiple transportation services to New York City and New Jersey. Weehawken offers spectaculars views of the New York City skyline, it is also renowned for being one of the most sought-after residential areas in the state offering a wide range of entertainment possibilities such as dining, retail venues, parks and public transportation.

ULMA Solution

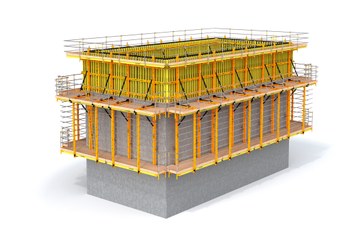

ULMA’s complete product portfolio was used in this project. The contractor used the Handset Panel Formwork MEGALITE system for the construction of walls and columns which is an ideal vertical formwork system that help to meet the deadlines of any concrete construction project because of its versatility and productivity. The modular formwork system was also used in the core of the building was erected with MEGALITE gangs. The light weight panels allow easy handling and a quick connection by using the MEGALITE Clamp. Around 43,000 SF of MEGALITE were delivered on the jobsite.

The contractor, Roy Rock LLC used the H20 Beam Slab Formwork ENKOFLEX shoring system to build all the concrete slabs. This system was chosen because it’s adaptable, easy to assemble, and adjustable to several height requirements that vary between 10’ to 14’ for this project. It is renowned for its versatility, safety and increase in productivity. Our clients recognize that the quality of the material is one of the biggest benefits about ULMA’s products because it allows the workers to move faster in a safe work-environment, “productivity is increased just by the quality of the material that we have from them” said Tony Monteiro, foreman at Roy Rock LLC. Along with the ENKOFLEX system, the contractor chose our Aluminum Shoring Post ALUPROP designed to support high loads and to meet any shoring requirements.

The design of the building required a special solution on the third floor due to the 23 ft. high height slab construction. ULMA offered as a solution the use of MEGAFRAME, a 20K Frame Shoring System, a galvanized steel frame handset shoring system that can accommodate most all shoring heights. Nearly 9,000 SF of MEGAFRAME was delivered to the jobsite.

We also offered our Rail Climbing Formwork RKS system as a solution to speed the construction of the shear walls with a hydraulic lifting mechanism acknowledged by our clients as one of our key feature products. This system provides high levels of safe climbing at height ensured by rails secured to the wall.