Description

The new access roads to the Dos Valires Tunnel are part of one of the largest infrastructure projects carried out in Andorra. They connect the towns of Encamp and La Massana through a complex orography reducing travel times.

In this case, the complexity laid on simultaneously executing several structures in different stretches while optimizing the material rotation.

ULMA solution

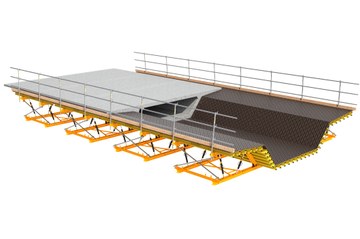

ENKOFORM HMK Formwork with falsework was used for casting the bridge decks, of more than 250 meters. In the cases where 28 m span stretches had to be covered, H-33 Trusses combined with heavy duty T-500 shoring towers were used. Two walers with the deck section shape were used to adapt the formwork the various deck cross sections. These walers were placed on the heads of the falsework. In turn, the walers supported the beams that determined each gang's dimensions. Using this fastening system, equipment stability is ensured during both the work stage and the formwork change. These gangs were stripped by means of a cable system fixed on the deck, making it possible to transfer the gangs to the next position without being dismantled. The assembling and dismantling labor is minimized in respect to other systems, especially when several similar pouring steps are carried out and when building several identical bridges or great length viaducts.

Safety is the basic requirement in this type of construction work. For this reason, a lateral passageway was provided on the cross section for the transit of people, along with a safety handrail. Structure 5, with five spans and two piers, was built with the same systems that were used throughout the construction project. An 11.5 m road passage and two open frames were erected on the piers in order to facilitate the structure stripping.

The pier at the junction of the three structures had been designed as a tripod on top of a plinth. The forks of different lengths and with 3.5 m width and a variable cross section were built using the same products as for the viaduct deck, making the most of the various construction stages. The gangs, of approximately 4 m, consisted of bottom formwork (ENKOFORM HMK), two formwork sides and one formwork panel as stopend. This solution provided a perfect concrete finish and enabled dismantling the formwork by parts. The support was made up of four DU-120 support beams and a series of shoring towers. These light supports, easy and fast to assembly, were afterwards moved by crane from one to the next pouring step. This way, the works were sped up and costs were considerably reduced.

The design of the falsework and the formwork for the construction of the pier cap used a combination of the systems ENKOFORM HMK, ENKOFORM V-100, beams and the shoring system fastened to the pier by means of MT Gantry Brackets.