Description

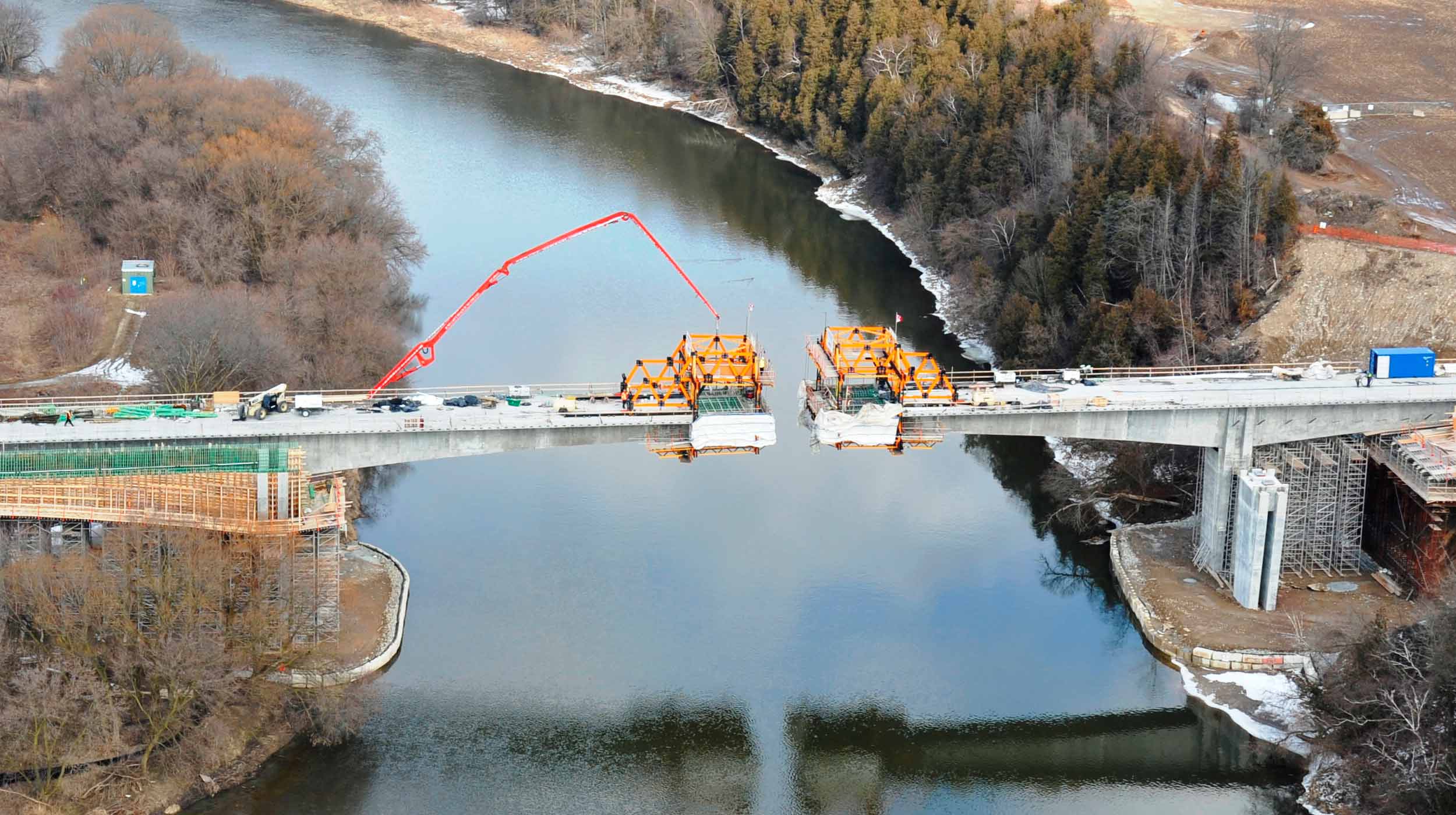

The bridge over the Grand River, first new crossing of the river since 1963, links two economically important areas, Kitchener and Cambridge. It moreover enhances the connection with one of the major motorways of the country, the 401.

With a length of 247 m, it consists of 4 spans. The largest one, 95 m, bridges the Grand River.

The construction method of on-site incremental segments for the longest span turned the bridge into the first one built in Ontario with this technique since the 80s. ULMA put the most advanced system and experienced specialists in the application of the system at the disposal of the customer to construct a bridge suiting a mountainous geography with a technique rather popular in Europe.

ULMA solution

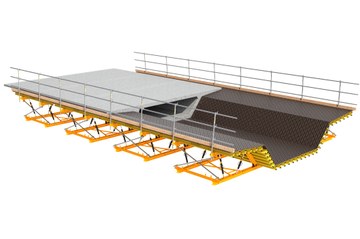

In this case, two Form Carriers CVS were used. They were placed at opposite ends, each one starting off from one pier of the span and moving forward simultaneously towards each other until the center of the span. A total of 19 segments of 4.75 m length each were built. The flexibility and easy adaptation of the system provided a powerful solution for the continuously varying bridge deck sections in each advance of the form carrier.

ULMA, in addition to the supply of the material, provided engineering service, pre-assembly of the structure and on-site assistance.

Based on the modular concept of the MK System, this form carrier adapted well to the different cross-sections. The inside and outside formwork was independent from each other which allowed of shorter work cycles. The use of MK standard components reduces the weight and costs of the equipment compared to other custom-made form carriers.

The piers of a height of 15 to 18 m were built with ORMA formwork on CR-250 Climbing Brackets. Each set of formwork with large working platforms is moved in a single crane lift to the next building stage.

This project has been carried out with ULMA concrete formwork systems