Description

This sports complex venue dedicated to tennis is a multipurpose and versatile center designed by the French architect Dominique Perrault.Built of steel, wood and glass, it houses various sports facilities. The Magic Box is the headquarters of the Madrid Tennis Master Tournament, as well as other international competitions.

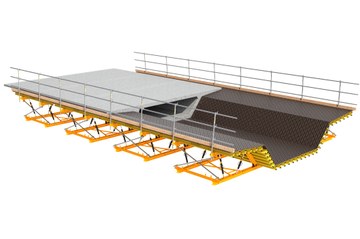

The building has mobile roofs that transform it into both an indoor and outdoor space.

This complex of 82,520 m2 displays a top view that is almost square, with dimensions of 159.90 x 167.10 m, and a height of 35 m. It has 3 indoor courts,16 outdoor courts, a parking area,as well as other types of establishments. The Magic Box is the only venue in the world where it is possible to play both indoors and outdoors in the same tournament.

ULMA Solution

Quality and speed were the goals of this project. CC-4 Horizontal Formwork was used for the solid slabs, applying the standard solution for the column heads. There was an average of 6,000 m2 of material placed on site.

For the 8 meters of height that the design required, ALUPROP Aluminum Props were used arranged in towers. The performance of this product, used to execute the slabs, was increased since it was not necessary to disassemble each 100 m3 tower, but rather, after each use, they were all transferred intact. Thus, it was possible to reuse materials, as well as to reduce work times by avoiding continuous assembly and disassembly.

The project contemplated 1.5 m thick fair-faced concrete beams with an excellent finish, which were made with ENKOFORM HMK formwork and shoring towers. So both systems, used frequently in civil engineering, displayed their versatility.

Just like the beams, the 1.5 m square base columns, with a height of almost 9 m, required a high quality finish. For this, ENKOFORM V-100 Vertical Formwork was assembled on site, which allowed for a single concrete pouring.

The 2,000 linear meters of wall were set up with ORMA modular formwork and Conventional Climbing Systems.