Description

Morumbi station, located in southern São Paulo, is part of Line 17 - Oro that will connect the Congonhas Airport to the Morumbi District of São Paulo. Led by the developers Camargo Corrêa Infra, this large urban transportation project will increase economic productivity and contribute to improving the quality of life for local residents, serving close to 41,000 passengers daily.

ULMA solution

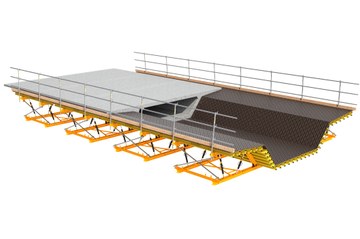

The main challenge posed by the Morumbi Metro Station project was finding an engineering solution that would create the support necessary to safely shore the entire structure, compensating for the lack of space available on-site. The MK Heavy Duty Truss proved to be an ideal solution for its ability to withstand heavy loads in limited spaces, safely spanning distances up to 18 m, swinging at 6 m above the Pinheiros River.

COMAIN Lightweight Panel Formwork was employed to execute the pillars and transverse beams at heights up to 4 m. It proved to be a versatile, flexible, and lightweight solution, which thanks to its wide range of panels can be adapted to varied geometries, making for excellent productivity on-site. Based on the MK System, the ENKOFORM VMK Timber Beam Formwork system was used to execute fair-faced concrete walls with an excellent finish.

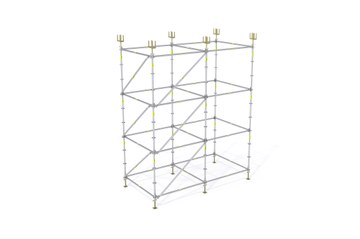

For the station slabs, the bridge deck formwork ENKOFORM HMK made it possible to adapt to different configurations while acheiving a high quality finish. This horizontal beam formwork system stands out for its great versatility, with the flexibility necessary to execute different geometries. The BRIO Shoring System served to shore the slabs; with its simple and rapid assembly system it proved ideal to support the ENKOFORM HMK Formwork System with its main and secondary beams.

Another aspect that the client considered key when choosing ULMA as a supplier was the guaranteed safety of the working spaces provided, even more important in this region with frequent high winds. With the MK System it was possible to install a 40 m walkway supported by heavy duty MK shoring, which together with the BRIO construction scaffold and BRIO temporary access system provided safe walkways throughout the site.

The construction company responsible for the project, Camargo Correa Infra, stressed the importance of the trustworthy service and quality of ULMA products that -- together with the logistical capability and effective planning that guarantees timely deliveries, as well as continuous assistance on site -- are necessary to successfully undertake projects of this magnitude and technically demanding nature.