Description

On the Cuiabá River in Brazil, construction is underway on a new bridge in balanced cantilever method that will link the Parque do Lago in Várzea Grande with the Atalaia Park in the capital. The main challenge has been not to impair or interrupt the navigability of the river.

"The main condition for this project was to preserve the navigability of the Cuiabá River, respecting all the guidelines of the Brazilian Navy. The bridge is 390 metres long, with a span of 240 metres and 120 metres of navigable lane, coinciding with the central span and taking into account the prerogatives of the Brazilian Navy", says Luiz Armino, site engineer, Rivoli construction company.

RIVOLI believes that, in addition to promoting economic development in the region, the execution of the project will alleviate the traffic on several roads in Cuiabá and Várzea Grande, which are currently busy. In addition, it will create a new access to the Marechal Rondon Airport, and reduce travel time between the two cities.

ULMA solution

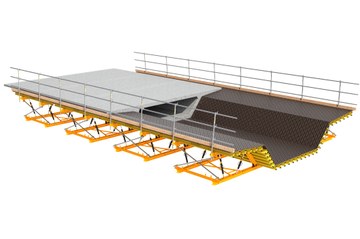

In a project like this, there are many challenges. To avoid affecting the environment and the use of shoring on the ground, the section over the Cuiabá River is being built with ULMA Construction's CVS Balanced Cantilever Formwork Carriage. This equipment has a hydraulic advance system, reducing the necessary work force and execution times. "The construction company RIVOLI has opted for this balanced cantilever method to overcome a span of 120 metres, increase productivity and meet the established schedule in the shortest possible time".

In addition to the use of CVS Balanced Cantilever Formwork Carriages to carry out the 1.5 to 5 m long segments, other products from ULMA's portfolio such as COMAIN and ENKOFORM formwork, T-60 shoring system, BMK climbing brackets and metal profiles have been used to build the piers and other structures.

"The safety of ULMA equipment brings productivity to the construction site, reducing project execution time. Today, the collaboration between ULMA and RIVOLI has reached a very high level of closeness. When there is a technical difficulty, we contact ULMA and they respond quickly, which facilitates and speeds up our production process," says Armino.