Description

The execution of the Port Complex of the Natural Gas Export Plant in Cañete has positioned Peru as a leader in the LNG industry of South America.

The aim of the project is gas transport. The construction work consists of a plant, a sea terminal for exporting, and a gas pipeline of approximately 300 km in length that connects the gas exploration field with the Pampa Melchorita Plant, and from here, to the LNG Plant between Cañete and Chincha.

For the execution of the sea terminal, a 1.4 km long pile bridge was built, extending from the coast to the loading platform. The pier structure is made up of: piles, cap beams, longitudinal beams, walers, prefabricated concrete slabs, handrails, and service pipes.

ULMA solution

Special panels, consisting of a metal frame and plywood, were designed for the formwork of the pier's pre-fabricated slabs. This versatile formwork provided excellent fair-faced concrete finishes, without holes, and a high performance that made it possible to execute 6 to 8 slabs of 9 m.

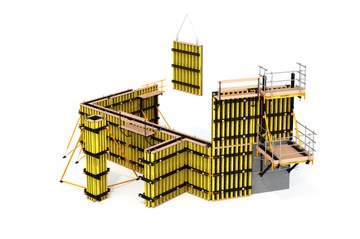

The construction of the walls and columns was carried out with ENKOFORM V-100, which adapted perfectly to the various configurations required.

A platform located under each of the axes of the pier was executed with the BRIO system. Additionally, a cantilever scaffolding structure was erected, with a length of 35 m, to perform painting and welding tasks, etc. This scaffolding was rotated from the first axis to the last one. This project has been the first in Peru with such magnitude of cantilever scaffolding.