Description

The new treatment plant has replaced the obsolete facility of Gigablok, in operation since 1981. The project entailed the execution of more than 40 buildings and structures of various functions and dimensions. The key to the construction work was to supply the corresponding material on time, to perform works simultaneously, and to layout the various systems precisely. All this required the most experienced engineers in working with complicated structures.

ULMA Solution

The septic tank has two structures with a high degree of complexity: radial walls with a 16 m diameter and a height of up to 12.9 m, made in 5 layers. It is worth mentioning two of the solutions provided in this facility:

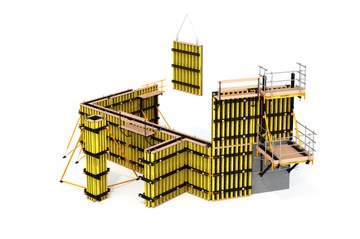

- The execution of 8 embedded columns for anchoring the circular system of pre-stressed cables. To do so, the design and construction proposed involved an integrated structure with elements of vertical modular formwork, H-120 beam system, and timber structures.

- The conic dome as septic tank roof system was made by designing a support structure in the shape of a pyramid by means of timber beams.

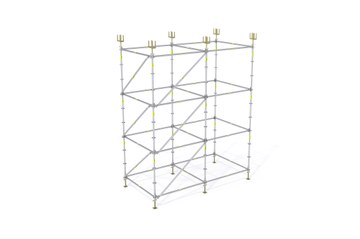

The roof structure was placed on an intermediate 12 m high platform built with beam formwork. The platform support system consisted of 50 shoring towers braced together with different heights due to the conic shape of the tank.

All solutions successfully applied in the first tank were used again in the construction of the subsequent tanks.

Secondary settling tanks

They consisted of 3 radial structures with a diameter of 20 m and a height of 5.5 m. The stringent concrete finish requirements demanded the use of a beam formwork system that would adapt to the particular shape of the tanks. The settling tanks were constructed using panel modules covering 1/8 of the circumference and the corresponding fillers.

Biological reactor

A reinforced concrete structure of more than 10,000 m2 and with 6.15 m high walls, constructed in monolithic technology using modular vertical formwork with a height of 3 and 3.3 m. Due to the level of design complexity, the execution process was divided into approximately 30 stages. A complete range of products, namely modular vertical formwork, horizontal beam formwork, propping systems with falsework and BRIO stairs, was applied during construction. Modular vertical formwork along with falsework was also usued in other buildings, such as the pumping stations and chambers and the sand chambers. For this reason, the rotation and re-use of material in the execution of the various structures enabled the highest optimization of the works in this project.