Description

The new hospital structure, designed according the most innovative standards in sustainability and functionality, combines the IRCC Galeazzi Orthopaedic Institute and the Sant’Ambrogio Clinic Institute, which together constitute the San Donato Hospital Group.

Galeazzi Hospital is the spearhead of the emerging Science, Knowledge, and Innovation Park project, housed in the Milan EXPO. The building, designed by the Binini Partners Studio, has a budget of 200 million euros. It will be a cutting-edge health centre that integrates inpatient services, research, and education, with a capacity of approximately 9,000 people daily, including patients, personnel, users, and students.

Located within the Milan metropolitan area, the new building boasts 150,000 m² spread across 16 storeys. Sustainability and environmental impact were paramount during the construction process, with special attention paid to environmentally-friendly building materials, renewable energy, and a total commitment to reduced CO2 emissions.

ULMA solution

For this emblematic project, ULMA not only provisioned innovative products but demonstrated clearly that close collaboration with the client, along with continuous onsite assistance, makes it possible to meet the demands of even the strictest timelines.

The solutions provided allowed for elevated productivity and rapid cycle times, while guaranteeing a high-quality concrete finish. The slabs were built using pre-assembled VR Tables, which allows for large surface-areas to be poured under a demanding timeline. The system provides significant time savings due to the fact that the tables can be moved to the following pour without disassembly, either vertically by crane or horizontally with the VR Lateral Carriage. With 6,000 m² of equipment we were able to guarantee a cycle of 1 storey every 3 weeks.

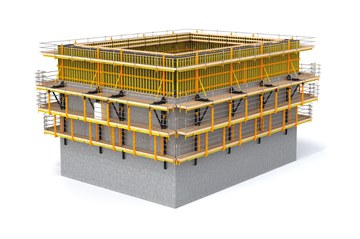

More than 7,000 m² of ORMA Panel Formwork and the ATR Self-Climbing System were used for the stairwells. This system’s hydraulic units were capable of lifting the entire structure simultaneously without the need for cranes, thus freeing them for other tasks onsite and increasing efficiency.

As on every worksite, safety was top priority. ULMA has a wide range of protection systems, of which two were used for this project: the MBP Fence Guardrail and SARE Cantilever Safety Net System. These protection systems made it possible to forego perimeter scaffolding completely.