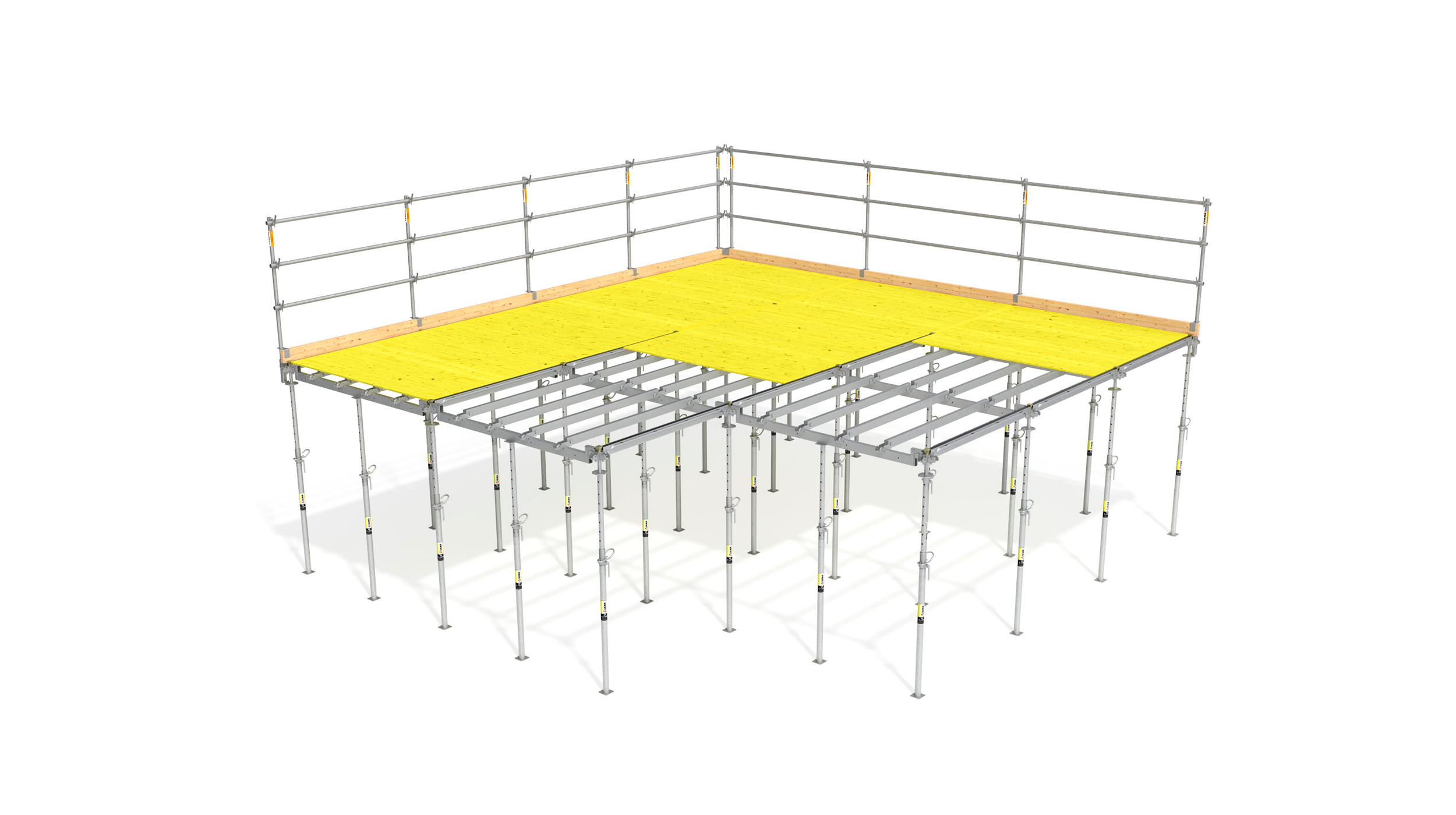

The ONADEK is a high-performing modular formwork system with easy assembly and maximum flexibility designed for the building sector. Ideal for making any type of slab, including those with complex geometries that incorporate drop beams, columns or shearing walls.

It provides remarkable reductions in assembly and dismantling times with high safety standards guaranteed for the worker, thanks to modular yet flexible structure and a fast and effective stripping process.

Modularity:

- Systematic and intuitive assembly and dismantling. Quick and basic training process.

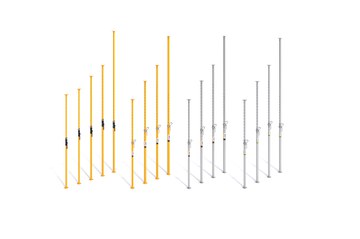

- Lightweight components that can be easily hung and raised by only one worker.

- Designed to minimize the possibility of assembly mistakes.

Flexibility:

- Maximum flexibility for adapting to any kind of geometry, solutions for starts and all kind of infillings (columns, walls, hang beams, capitals...).

- Possibility to overlap lying timber beams.

- PATENTED: Innovative overlapping metallic beams.

Safety:

- Assembly and dismantling from the bottom up.

- Easy and safe stripping due to the drophead system (drop distance 12 cm).

- A wide grid width and open-plan makes the workspace more ample and safe.

- High stability grid due to the strong connection between all individual parts.

- Most of the formwork can be dismantled and reused on the third day, leaving the drophead together with its prop as the only remaining system components.

- Low propping rate: 0.4 props/m² for pouring and 0.2 props/m² for backpropping.

- Up to 50% savings on equipment compared to a traditional timber beam system, thanks to early striking; also on plywood.

- Delivery savings thanks to less equipment needed on site.

- More free time for the crane to dedicate to other activities.

- After the system is stripped by early drophead striking, the material goes from the deck directly to the pallet, without dropping it down to the ground.

- Long-lasting equipment. Robust components in high-strength galvanised steel, protected against the damage of impact.

- Less damage to plywood thanks to a system protected edges and no need for nailing.

- Avoids extra replacement costs for scrap timber beams, compared to traditional timber beam systems.